Is it worth the time and effort to do a serious tire survey? The simple answer is YES. Tires are a significant operating expense for every fleet. With the average price of a commercial truck tire in the $500 price range a tire survey can be crucial in getting the most out of your tires. A comprehensive survey should include tires currently running on vehicles and those sitting in the scrap pile.

Inspections by drivers and technicians on a regular basis are key to identifying both tire and vehicle issues. Regardless of who is performing the survey, they need to have a basic understanding of tread wear. Drivers can also provide additional input, such as vehicle handling, that could be the result of alignment issues, wheel balancing, etc. Inspection of the tires that are still on the vehicle will allow for repairs to be made to the vehicle causing the irregular wear. If you wait until the tires are in the scrap pile, it will likely be too late.

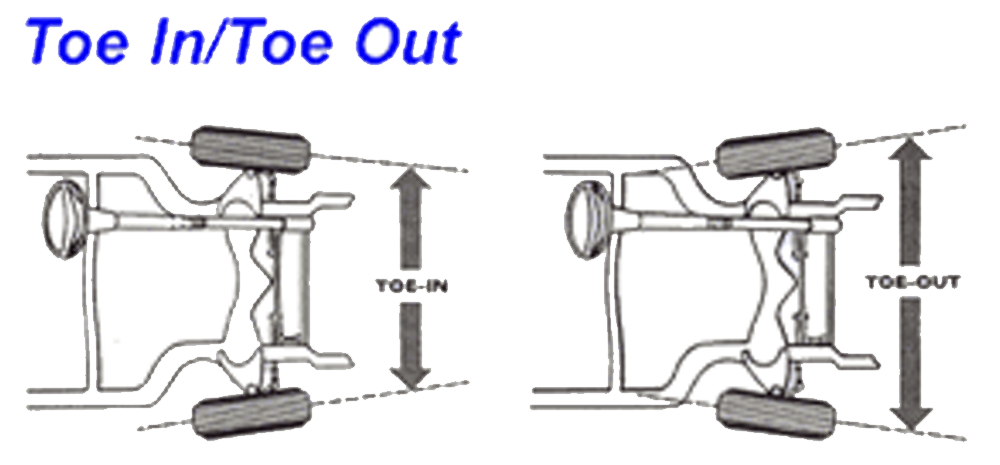

Tires with one sided wear, heavy wear on one shoulder or feather wear across the tread surface are typically related to vehicle alignment issues. For example, a common irregular wear condition is outside shoulder wear on both steer tires which is typically a result of excessive toe-in. Toe is the alignment angle between the two steer tires in the longitudinal direction (see figure 1). Excessive toe-in or toe-out can lead to accelerated tire wear. These tires will require replacement before reaching their full mileage potential.

Another common type of irregular wear found in routine inspections is where one steer tire has outside shoulder wear and the opposite steer tire has inside shoulder wear. This is typically caused by misalignment of the drive axles. When tires develop wavy and cupping type wear around the tread the finger can be pointed to the tire/wheel assembly being out of balance.

When a tire exhibits significant irregular wear 360 degrees around the tread and is a combination of depression, cupping, wavy and heel/toe wear, then the tire has been run substantially underinflated for an extended period. This is commonly found on inside duals where the outside tire is running at the proper inflation pressure while the inside dual may be 30 psi or more below the proper inflation pressure.

Routine air pressure checks will clearly reveal tires with punctures or leaking valve stems/cores. Getting these tires thoroughly inspected and repaired quickly could save an emergency tire-related roadside service call and preserve the casing.

Inspection of your scrap tire pile will help identify many of these same issues. However, repeating these inspections on a regular basis will help determine if your tire survey and corrective actions are providing the anticipated benefits. Scrap tire inspection is also a good way to determine if you are getting the most out of your retread program. If your goal is to retread every casing two times, your scrap tire pile should be comprised of second worn out retreads. If your analysis reveals that most of the tires in the pile are only retread #1, there is an issue. Why was the tire rejected by the retreader for the second retread? Was it too many nail punctures? Rubber degeneration due to running underinflated?

As an example, one particular fleet’s goal was to retread casings two times. Their scrap tire analysis revealed that the tires in the pile were clearly second retreads, however, the tires still had most of their tread depth remaining. These second retreaded tires were wearing faster after only a few months in As an example, one particular fleet’s goal was to retread casings two times. Their scrap tire analysis revealed that the tires in the pile were clearly second retreads, however, the tires still had most of their tread depth remaining. These second retreaded tires were wearing faster after only a few months in service. Based on the harsh service vocation this particular fleet operated, it was not worth the cost to retread a second time. Their policy is now to retread just one time!

Another reason for a good tire survey is that fuel economy dramatically declines when tires are not wearing smoothly and evenly. Early identification of these tire problems will improve overall vehicle fuel economy. Training drivers and technicians how to properly and thoroughly inspect and analyze tires will help optimize your tire program and reduce costs. Always work with your local tire professionals who are available for training and help in performing tire surveys.

Figure 1 Source: Tire Information Center